Varanasi (earlier Benares), UTTAR PRADESH :

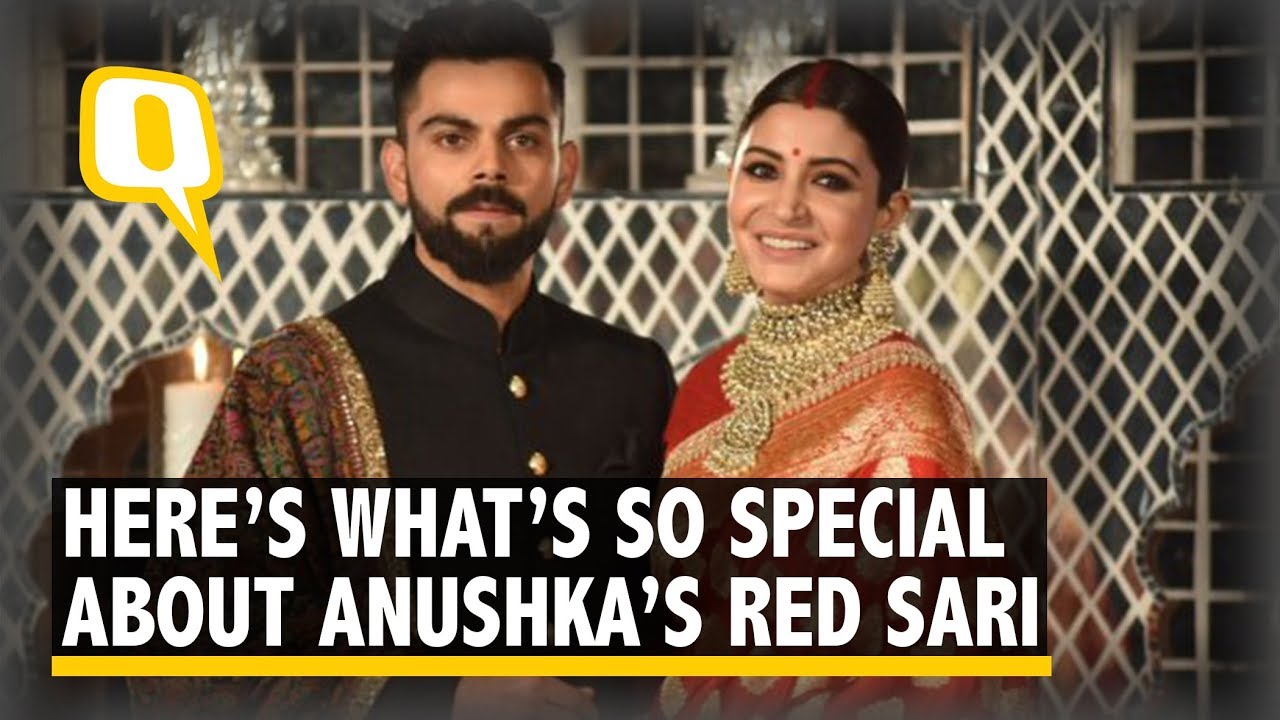

Muazzam Ansari of Benares was among several thousands who were glued to the television screen for news of the glitzy Virat Kohli and Anushka Sharma wedding. But unlike several others, Ansari was watching the ‘Indian wedding of the decade’ closely for a very special reason – the gorgeous Banarasi red saree that Anushka wore for her reception in Delhi.

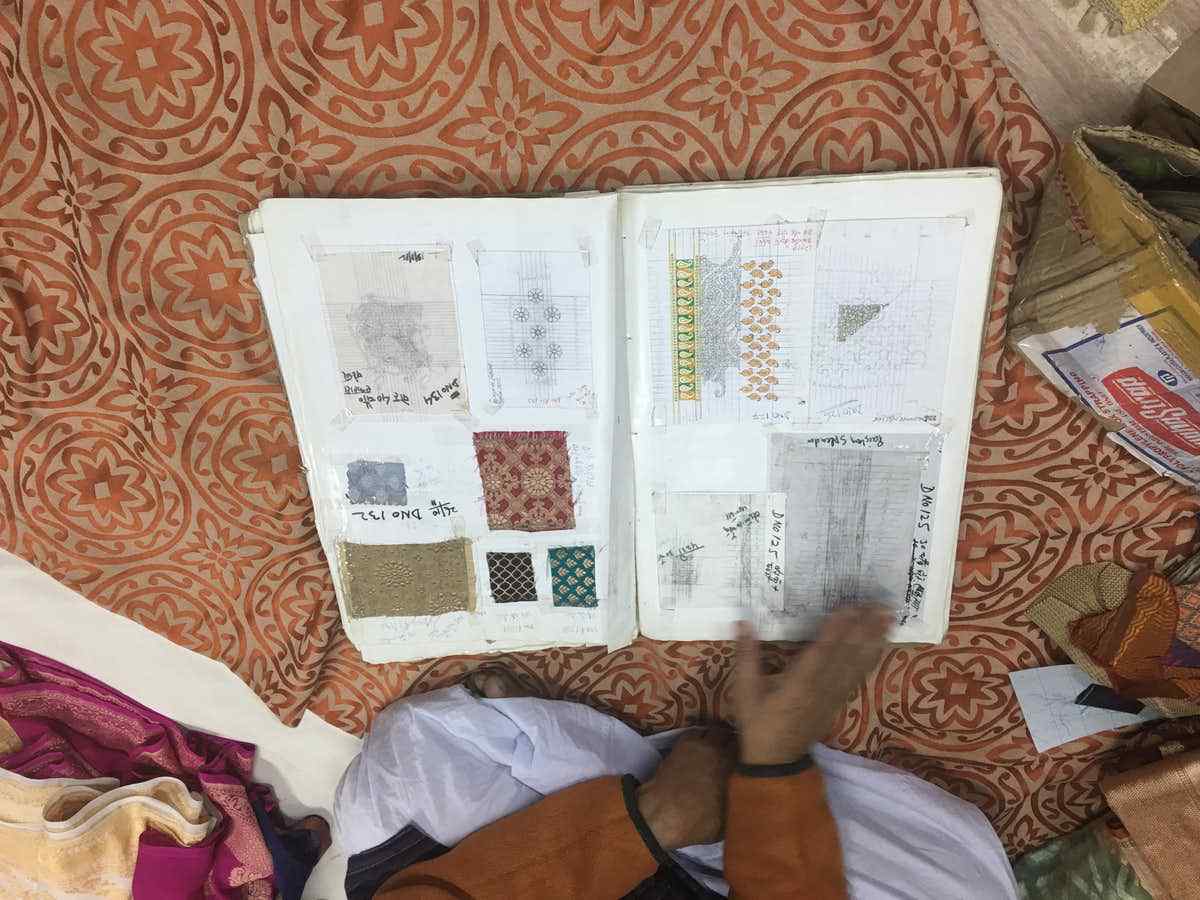

Ansari was among a team of three craftsmen who toiled day and night for two months to create the exquisite saree. And the saree maker says having the world fawn over it was a moment of great pride.

(Photo Courtesy: Vikrant Dubey)

As the Virat-Anushka reception photos went viral, Ansari was quick to post photos of the saree on his Facebook page – a move that would quickly bag him the nickname, ‘Anushka Sharma’s Saree Man’.

Anushka’s saree called for extensive planning. After the designers decided on a Banarasi saree came the tough part – selecting a craftsman from the thousands of skilled workers in this trade in Benaras.

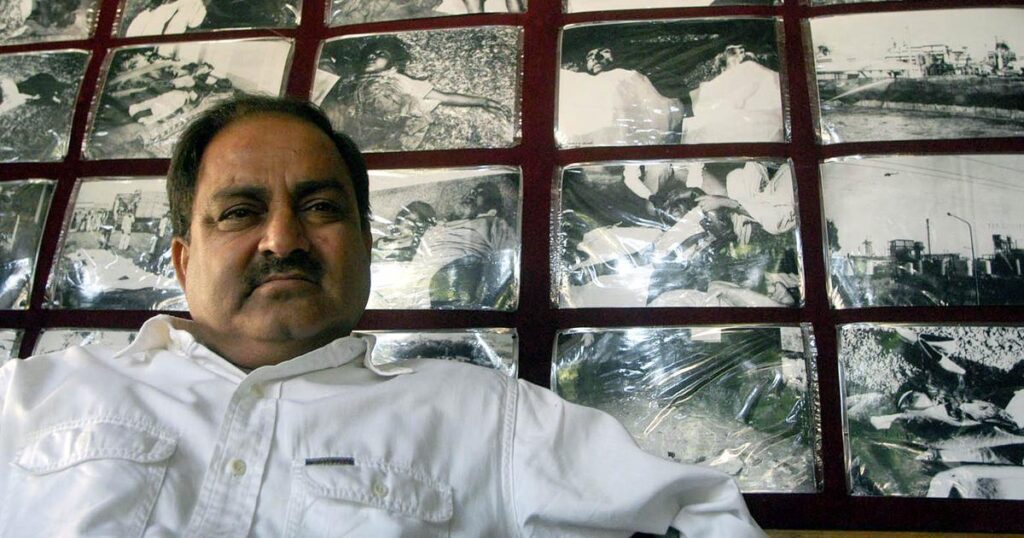

Maqbool Hassan Gets the Job

(Photo Courtesy: Vikrant Dubey)

The important task was given to Maqbool Hassan from Peeli Kothi in Benaras, who has been in the business since 1966. Hassan, whose family has been engaged in the business for over two centuries, is also credited with having created a saree for Aishwarya Rai and a sherwani for Abhishek Bachchan.

(Photo Courtesy: Vikrant Dubey)

After the Cottage Emporium in Delhi reached out to Maqbool Hassan with the order to create the sari, he set about creating a team of three of his most skilled craftsmen. Among his top three were Muazzam Ansari, whose work is already popular in Benaras, despite the fact that he only joined the industry five years ago. What’s more, fans of Ansari’s work reportedly compare his work with craftsmen with over 20 years of experience.

Months of Secret Planning & Weaving

(Photo Courtesy: Vikrant Dubey)

As soon as the dates for Virat and Anushka’s wedding were decided, the designers zeroed in on the Banarasi saree for their Delhi reception.

Then began the hunt for the saree design. After much debate and decision, the creators decided on a bright red colour with traditional golden work. The entire process of selecting a colour, finalising a design, and finishing the design took six months. All of it was done in absolute secrecy.

(Photo Courtesy: Vikrant Dubey)

Once the design, colour, and fabric was finalised, it was time for the actual weaving. Banarasi sarees are made on handlooms – each thread and the colour for every bit of the design is put in place by hand.

The saree called for three weavers to work day and night for 45 days. It took another 15 days to add the finishing touches, taking it to a total of 60 days.

Painstaking Effort

(Photo Courtesy: Instagram)

A mixture of silk and chiffon was used to make the saree in order to create an outfit that was both soft and light, despite all the embroidery and the seemingly-heavy work on it. The craftsmen also ensured that the saree did not have a glittery shine, even with real gold being used for the zari – with each motiff being worked on separately.

The three craftsmen tasked with making the saree had to work simultaneously on the weaving, and the absence of even a single craftsman made weaving impossible. With all the work that has gone into the saree, it is small wonder why Banarasi sarees are known for their timeless allure.

(This article was first published on QuintHindi.)

source: http://www.thequint.com / The Quint / Home> Entertainment / by Vikrant Dubey / December 27th, 2017

Prise & sari order contact no.